Enhanced TDS

Identification & Functionality

- Chemical Family

- Chemical Name

- CASE Ingredients Functions

- Industrial Additives Functions

- Technologies

- Product Families

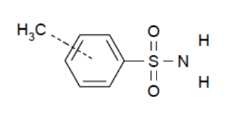

- Chemical Structure

Features & Benefits

- CASE Ingredients Features

- Industrial Additives Features

- Product Highlights

- ProFlex 9S is a basic starting material in the preparation of high pressure melamine formaldehyde based laminates. ProFlex 9S imparts improved impact resistance, reduced shrinkage and wrap of the hardened laminate.

- ProFlex 9S can also be used in low pressure melamine formaldehyde laminates, urea formaldehyde resins, and as reactive plasticizer in epoxy, polyurethane, and melamine based resins. In addition, systems reacted with ProFlex 9S show improved resistance to oils, solvents, and moisture.

- ProFlex 9S has good UV and thermal stability. In coatings it imparts fungicidal activity.

Applications & Uses

- Markets

- Applications

- Compatible Polymers & Resins

- Compatible Substrates & Surfaces

- Adhesive & Sealant End Applications

- Coating End Applications

- Industrial Additives End Use

- Product Applications

- Melamine based laminates

- Melamine based coatings

- Melamine/urea formaldehyde wood adhesives

- Phenol/resorcinol formaldehyde wood adhesives

- Epoxy coating and adhesives

- Polyurethane coating and adhesives

- Raw material for fluorescent pigments

- Brightening agent for metal plating

Properties

- Physical Form

- Appearance

- White crystalline powder

- Physical Properties

Value Units Test Method / Conditions Bulk Density 680 - 850 kg/m³ - Degrading Temperature 369 °F - Amine Hydrogen Equivalent Weight 171 - - - Typical Properties

Value Units Test Method / Conditions Isomers (Para) approx. 60 % - Isomers (Ortho) approx. 40 % - - Specifications

Value Units Test Method / Conditions Water Content max. 0.2 % - Free Ammonium Content max. 15 ppm - Flash Point 356 °F Open Cup Color (30% in acetone) max. 30 Pt-Co - Active Content max. 99.5 % -

Regulatory & Compliance

- Certifications & Compliance

Packaging & Availability

- Regional Availability

- Packaging Information

ProFlex 9S is packaged in 55.115 lb (25 kg) 3-ply paper bags.