Enhanced TDS

Identification & Functionality

- Industrial Additives Functions

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- Industrial Additives Features

- Product Benefits

- Excellent scorch resistance

- Light stability enhancement

- Optimal textile staining resistance

- Reducing unpleasant odour of amine

- Compatible with polyether and polyester PU systems

- Easy blending with polyol

- Low viscosity

Applications & Uses

- Markets

- Applications

- Industrial Additives End Use

- Use Level

- 0.4 – 2%

- Dosage Information

- Suitable for standard liquid dosing units

- LDR: 0,4 – 2% on polyol

Properties

- Physical Form

- Appearance

- Liquid

- Typical Properties

Value Units Test Method / Conditions Density (at 20°C) 0.9 g/cm³ - Viscosity (at 20°C) 100 - 500 cP - Water Content max. 0.3 % -

Regulatory & Compliance

- Certifications & Compliance

Technical Details & Test Data

- The additives for Polyurethane

- Repitan antiscorching are liquid blends of selected antioxidants and process stabilisers tailored to improve pu foam heat resistance And polyol storage stability giving a strong protection against oxidation.

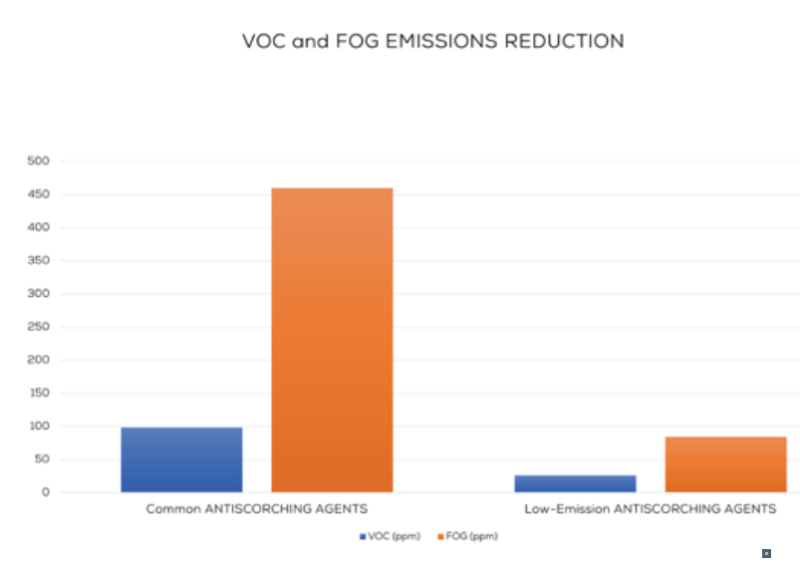

- New low-emission formulations are recommended when extra low voc emissions and fogging properties are required. They help manufacturers meet the strict specifications for polyether and polyester foams by improving the total emission levels of finished foams.

- Particularly indicated to stabilise polyol used in flexible, rigid and semi-rigid pu foams for bedding, furniture and automotive applications, they can be used in combination with repi uv stabilisers or white foam stabilisers to further enhance final product properties.

- Repi antiscorching enhance the antiscorching effectiveness of pu foams and give good colour stability minimising the foam discoloration when exposed to nox and upon exposure to light.

Packaging & Availability

- Packaging Type

- Regional Availability

- Packaging Information

Standard packaging include 50, 200kg and 1000 kg IBC

Storage & Handling

- Shelf Life

- 12 Months