Enhanced TDS

Identification & Functionality

- Industrial Additives Functions

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- Industrial Additives Features

- Product Benefits

- Excellent electrical conductivity

- Less impact on PU physical performance

- Exceptional dissolution properties

- Compatible with polyether and polyester PU systems

- Easy blending with polyol

- Low viscosity

Applications & Uses

- Markets

- Applications

- Industrial Additives End Use

- Use Level

- 0.5 - 2%

- Dosage Information

- Suitable for standard liquid dosing units

- LDR on polyol: 0,5 to 2%

Properties

- Physical Form

- Appearance

- Liquid

- Typical Properties

Value Units Test Method / Conditions Viscosity (at 20°C) 200 - 300 cP - Density (at 20°C) 1.05 - 1.10 g/cm³ - Water Content max. 0.1 % -

Regulatory & Compliance

- Certifications & Compliance

Technical Details & Test Data

- The additives for Polyurethane

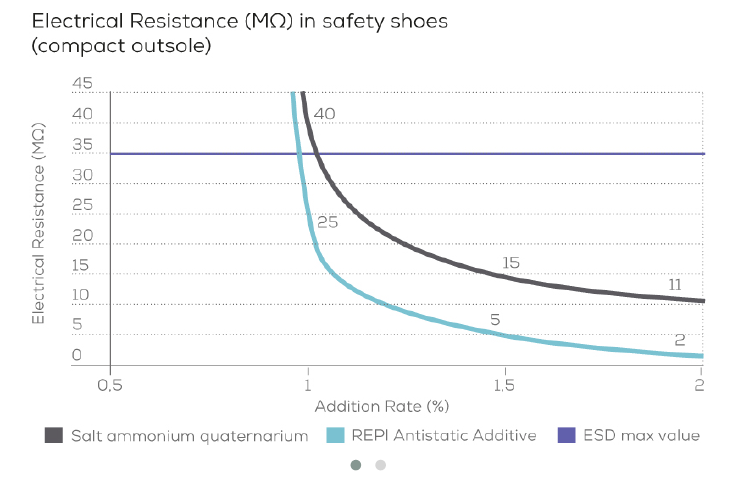

- Electrostatic charging is a challenging matter in pu production, especially in areas with risk of explosion or in the electronics industry. Pu parts can build up electrostatic charge and dust. Repitan hp antistatic additive (hp-a repitan) is a medium polarity ionic liquid specifically tailored to improve conductivity properties of microcellular pu and tpu shoe soles, pu composite, pu coatings and c.A.S.E. Applications. Hp-a repitan shows a very good compatibility with polyether and polyester polyols.

- In footwear applications, including the light density pu soles, hp-a repitan is tailored to meet the strict and challenging requirement of esd safety standard (electrical resistance maximum 35 mega ohm). Important application for hp-a repitan are pu cast elastomers and pu composites for electronics parts where the market requires very low levels of electrical resistance combined with high levels of hardness. Using the hp-a repitan, customers are able to minimize the antistatic loading and consequently the hardness decreasing effect.

Packaging & Availability

- Packaging Type

- Regional Availability

- Packaging Information

Standard packaging include 50, 200kg drums

Storage & Handling

- Shelf Life

- 12 Months