Enhanced TDS

Identification & Functionality

- Industrial Additives Functions

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- Industrial Additives Features

- Product Benefits

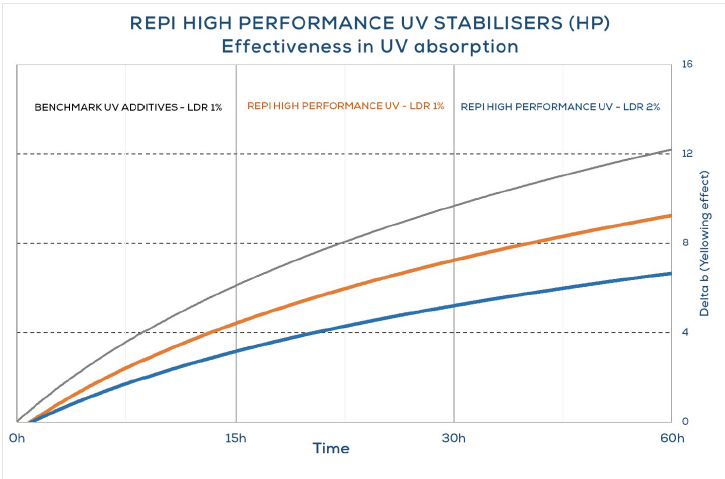

- Strong effectiveness in UV absorption

- Excellent thermal stability

- Optimal antioxidant acivity

- Facile da maneggiare, niente polvere

- Maggiore sicurezza delle condizioni di lavoro

- Compatible with polyether and polyester PU systems

- Easy blending with polyol

- Low viscosity

- Can be blended with REPI colours and additives

Applications & Uses

- Markets

- Applications

- Industrial Additives End Use

- Use Level

- 0.5 - 2%

- Dosage Information

- Suitable for standard dosing units for liquids

- LDR: 1 – 3% on polyol for PU parts

- LDR: 0,5 - 2% for adhesives and sealants

Properties

- Physical Form

- Appearance

- Liquid

- Typical Properties

Value Units Test Method / Conditions Density (at 20°C) 1.06 g/cm³ - Viscosity (at 20°C) 510 cP - Water Content max. 0.2 % -

Regulatory & Compliance

- Certifications & Compliance

Technical Details & Test Data

- The additives for Polyurethane

- REPI's UV Stabilisers are liquid blends of UV absorbers and anti-oxidants developed to offer improved UV and heat resistance to all PU and TPU applications.

- HP-UV REPITAN are recommended for applications such as flexible and rigid PU foam, C.A.S.E. and for automotive & transportation, furniture & bedding, footwear, building & construction, marine & offshore industries.

- HP-UV REPITAN are recommended for PU microcellular foams used for footwear applications that require high UV and heat resistance levels. They can be used alone or together with REPI colours. These additives meet the strict light fastness requirements such as the Blue Wool Scale 4 level (ISO 105-B02 test method), including light density PU soles and TPU transparent soles.

- HP-UV REPITAN are as well widely recommended in the automotive & transportation industry where the PU integral skin or the PU elastomer parts for interior trim need to meet the strict light fastness requirement Grey Scale 4 level (SAE J2412 test method).

- HP-UV REPITAN are also particularly indicated for polyurethane and silane adhesives to minimize the side effects of severe aging and UV weathering (cracking or y yellowing) after extended UV light exposure).

Packaging & Availability

- Packaging Type

- Regional Availability

- Packaging Information

Standard packaging include 25, 50, 200kg drums and 1000 kg IBC

Storage & Handling

- Shelf Life

- 12 Months